Questions? We've got answers.

Building upon over a decade’s worth of experience with turbocharged Audi and VW engines, including over half a decade with direct injected engines, APR’s Engineers have taken the Golf R and S3 to ground breaking levels of performance without compromise.

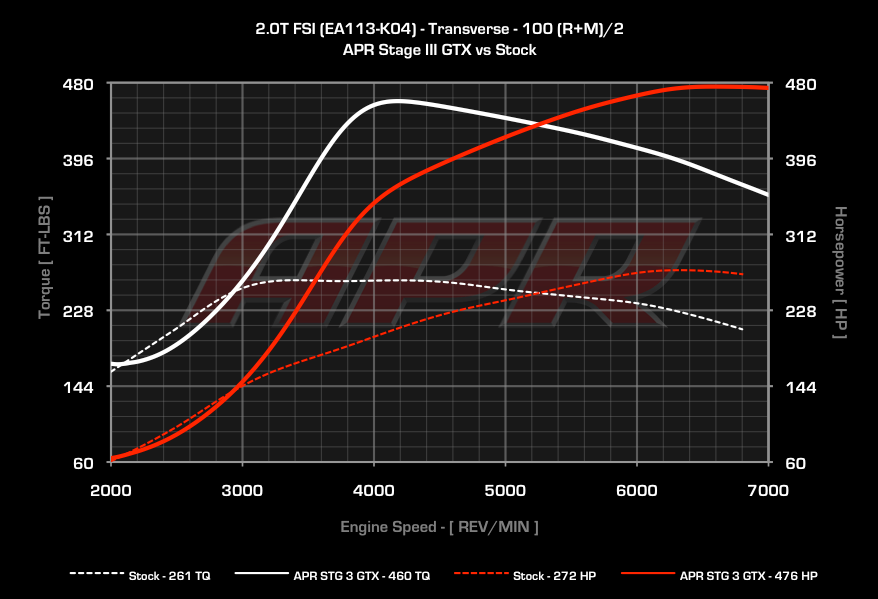

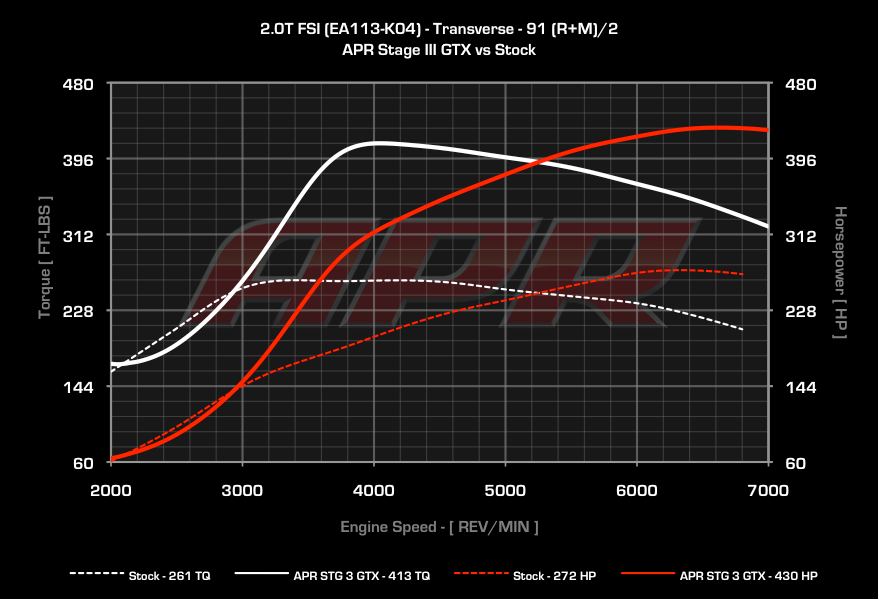

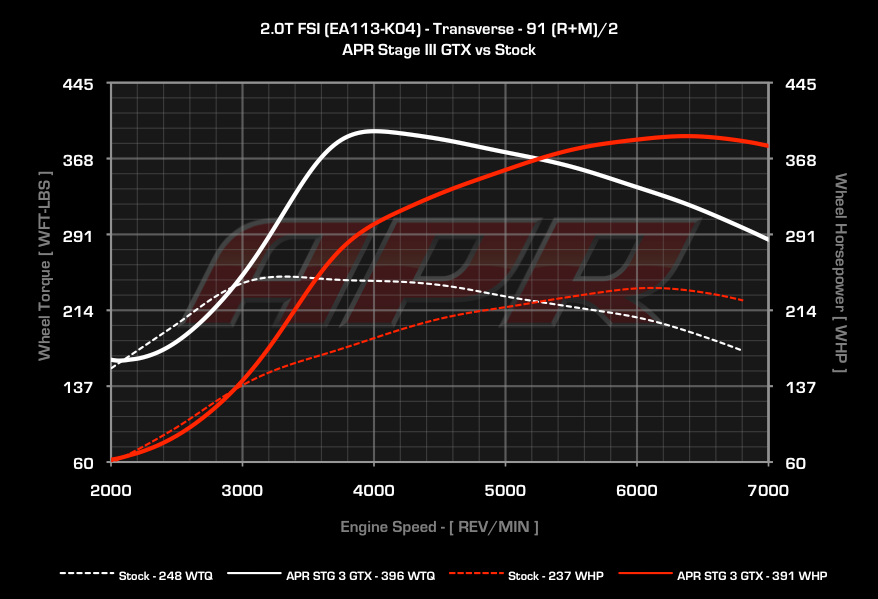

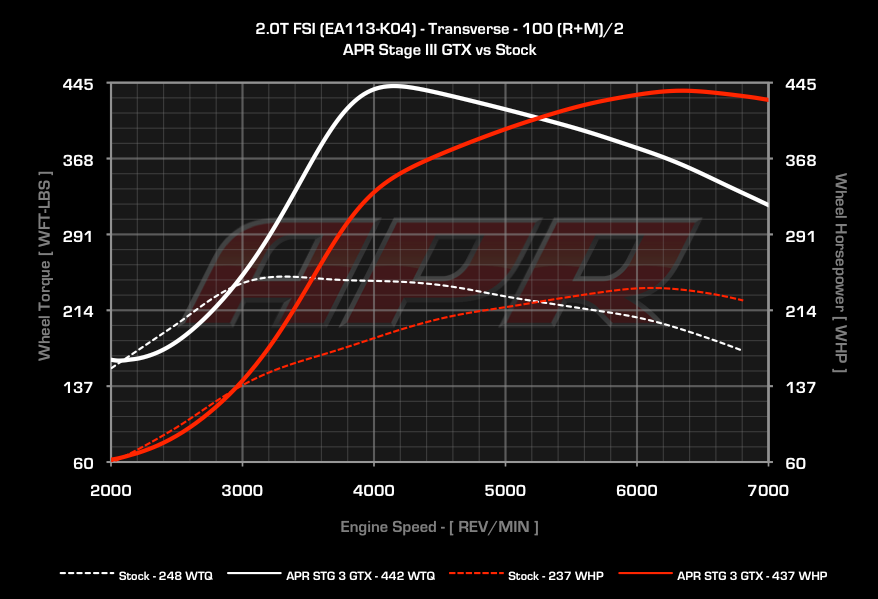

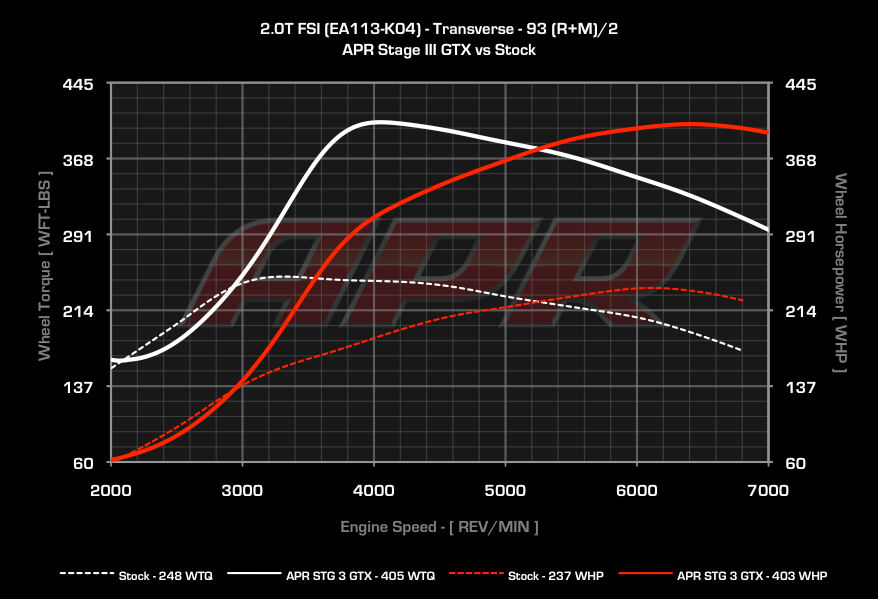

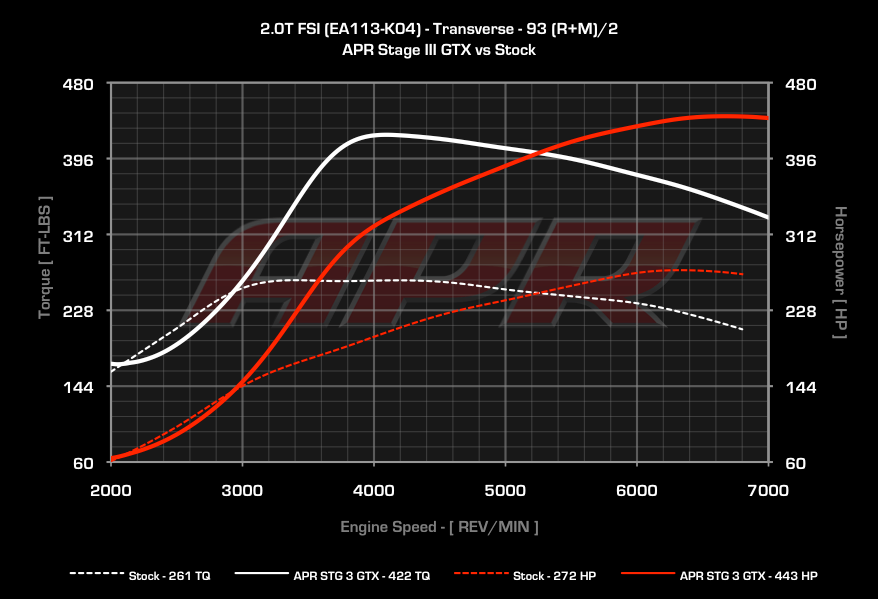

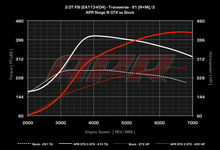

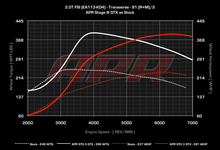

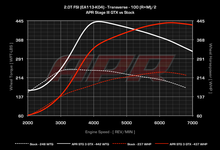

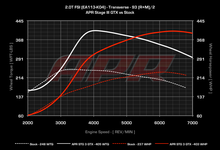

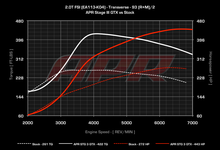

APR is pleased to introduce the Golf R and S3 Stage III Turbocharger System. Producing over 440 horsepower on 93 octane and over 475 HP in racing configurations with nearly no increase in turbocharger lag over the vehicle’s factory setup, Stage III GTX places the 2.0T's accelerative performance in the same league as that of large V8 supercharged muscle cars and sub $400,000 exotic sports cars. Thanks to the Golf R's and S3’s all-wheel drive system, power delivery is unlike anything previously experienced in standard form. As you hear a new exotic growl from your exhaust system, expect exhilarating g-force levels sure to put a huge grin on your face!

Important note* While the hardware in this listing is compatible with your vehicle it is possible that the required tuning is not. To confirm ECU tuning is available for your car, your vehicle's ECU box code must be identified. If you own VAG COM, OBDeleven, Carista, or have access to factory VW/Audi diagnostic tooling, you can follow this guide to identify your ECU box code. You can also visit either New German Performance shop location and our staff will be happy to assist. The customer assumes all risk if this turbocharger purchased and installed without first confirming the required software is available. No returns are accepted for installed turbocharger kits.

Turbocharger

At the heart of Stage III is a GTX2867R turbocharger, consisting of the latest technologies from Le Mans’ winning turbo manufacturer, Garrett Honeywell. The internally gated unit features a fully-machined, ten-blade billet compressor wheel and a dual ball bearing oil and water-cooled CHRA. APR’s Engineers spent countless hours testing turbine inlet and A/R sizes in order to decrease turbocharger lag without negatively impacting peak power. The newly developed compressor housing utilizes anti-surge porting, which greatly complements the lightning fast spool characteristics of this unit and grants APR’s Engineers the ability to deliver massive levels of torque inducing boost pressure, even in the lower RPM range.

Each turbocharger unit is assembled and clocked in house at APR with the necessary brackets to ensure proper wastegate fitment and orientation. Each wastegate is then calibrated for precise operation and control to ensure seamless integration with the expertly recalibrated OEM engine management system.

APR Stage 3 Software

The factory Bosch MED 9 engine management system is responsible for proper operation of the engine in all conditions. With built in compensational data for environmental variables and varying load conditions, the factory ECU is far more complex and intelligent than units found in other vehicle makes and marks.

With the significant amount of changes included in the APR Stage III Turbocharger System, APR’s Engineers spent months recalibrating the engine management system to operate smoothly as if intended by the OEM. Thanks to APR’s incredible proprietary calibration suite, data logging software and full access to the coding structure of the ECU, appropriate and intelligent changes are made to ensure flawless drivability and excellent performance without compromise.

APR’s EMCS program switching technology puts control of the ECU in your finger tips allowing you to access modes for standard pump fuel, high output race fuel and even reduced output valet modes to protect your vehicle against improper use by other individuals. This technology is patented by APR and is found nowhere else in the world. It’s Performance Without Compromise only APR can deliver!

Exhaust Manifold

Attached to the turbocharger is APR’s investment-cast, super alloy, nickel-chromium-based Inconel 625 Manifold featuring APR’s Sequential Exhaust Pulse runner lengths. Unlike hand welded tubular manifolds, Inconel is a very high temperature resistant material designed to withstand extreme exhaust gas temperature changes without expanding, contracting, melting or cracking under stress. This material is typically found only at the highest levels of professional motorsport racing where reliability is essential to success.

Investment-cast Inconel features heat retention characteristics which aid in turbo response by keeping exhaust velocity high. Ensuring each exhaust pulse arrives at the collection point without collision is critical to producing lightning fast response and immediate torque delivery. Using 3D modeling and computational fluid dynamics software, APR’s Engineers designed varying short runner lengths calibrated to deliver sequential exhaust pulses without collision. A reduction in backpressure from the high flow design directly enhances power delivery.

Each manifold is investment-cast in the United States of America and machined in house on APR’s CNC machines to ensure high casting tolerances, repeatable results and strict quality control. The thick casting material reduces unwanted exhaust noise leaving behind a powerful and exotic growl.

All of these characteristics result in a manifold designed without compromise backed by a confidence inspiring lifetime warranty.

Induction and Charge Piping

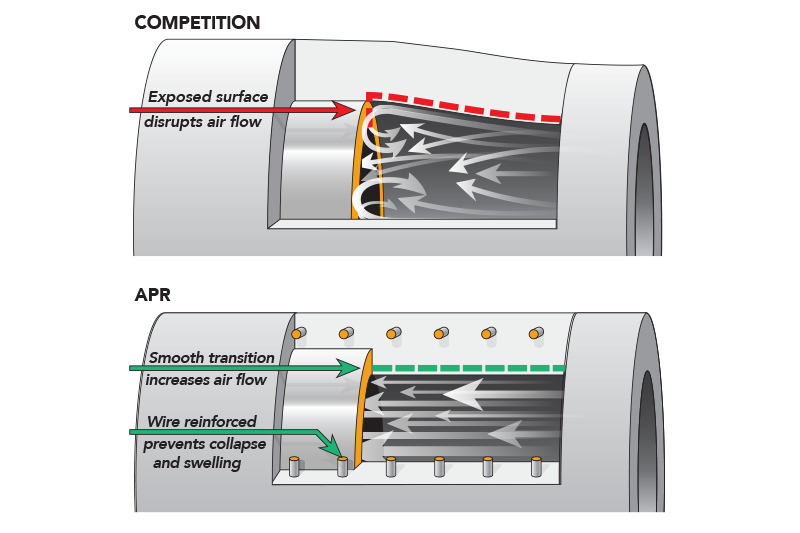

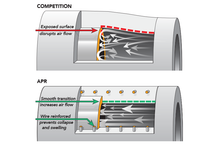

Wire reinforced, multi-ply silicone hoses provide an unrestricted path for airflow to enter and exit the turbocharger at over 1,000 kilograms per hour. The ultra rigid design ensures boost and vacuum piping will not swell or collapse causing leaks and restrictions in the induction and charge piping system supporting boost response and turbo recovery. Each hose is engineered to fit properly into the Golf R and S3 engine bay with all necessary emissions and reference ports securely affixed.

APR’s Easy-Flow Silicone Hose design features stepped mounting surfaces for smooth transitions from one pipe to another. Traditional designs simply sit on top of each other, often resulting in a disruptive airflow path. By using the stepped design, hoses fit properly without airflow restrictions, resulting in the most ideal path for moving air through the turbocharger and into the engine.

Turbo Outlet Pipe

To provide unrestricted and smooth airflow from the turbocharger to the intercooler, the APR Stage III Turbocharger System includes a cast enlarged turbo outlet pipe to properly deliver the additional airflow from the larger turbocharger.

Mass Airflow Housing

The Golf R and S3’s engine management relies on load calculations to accurately control the engine. Calculations are made by measuring airflow across the Mass Airflow Sensor and this is a critical component of the APR Stage III Turbocharger System.

The small and restrictive factory unit is removed and replaced with the much larger housing. To ensure accuracy, APR’s MAF housing is cast in the United States of America and CNC machined in house at APR to ensure repeatable results. The long, precision-machined housing features a honeycomb airflow straightener to further aid in accurately reading airflow levels. Simply enlarging the MAF housing is not permissible without accurate adjustments to the factory engine management system, which is included with APR Stage III Turbocharger System.

Oil and Coolant Lines

APR’s oil and coolant lines are specific to the Golf R and S3 Stage III System and provide years of leak free operation. The oil lines feature flexible braided stainless steel with CNC mandrel bent hard-lines for specific and clean hose routing as if intended by the OEM.

High Pressure Fuel Rail

The factory Golf R and S3 gasoline direct injection injectors require higher than factory fuel rail pressure to achieve targeted air fuel ratios under high load, wide open throttle operation. APR’s Low Pressure Fuel Pump delivers the desired volume of fuel to the APR High Pressure Fuel Pump, which provides increased fueling headroom over the factory unit. However, the factory High Pressure Fuel Rail Valve limits maximum rail pressure below the desired level. The included APR High Pressure Fuel Rail Valve is calibrated to increase the maximum rail pressure to levels necessary for proper operation.

In doing so, APR’s able to support far higher horsepower levels than achievable on the existing APR Stage III Turbocharger Systems without the need to alter the factory, correct spray pattern, injectors. This results in smoother part throttle operation, factory-like cold starts and fewer unburnt hydrocarbons emitted from the tailpipe under all conditions compared to other fueling options.

Downpipe

The GTX2867R internally gated turbocharger unit features a Garrett five-bolt flange, which differs from the OEM turbocharger flange. To support this design, the APR Stage III Turbocharger System includes a hydroformed 3” stainless steel exhaust downturn, which mates directly to an APR Midpipe, Downpipe or Turboback Exhaust System.

Bracketry

No matter how small the part, each piece of the APR Stage III Turbocharger System oozes with quality evident in pieces like the Stage III's laser cut ancillary brackets and carriers.

Spark Plugs

Proper temperature range spark plugs are included with each APR Stage III Turbocharger System.

Required Components

In order to install the Golf R Stage 3 Turbo Kit, APR requires that you have a high pressure fuel pump, aftermarket high flow intake, APR Midpipe (not necessary if you already have an APR Catback or Turboback exhaust), and an upgraded front mount intercooler.