Building upon over a decade’s worth of experience with turbocharged Audi and VW engines, including over half a decade with direct injected engines, APR’s Engineers have taken the 2.0T FSI to ground breaking levels of performance without compromise.

APR is pleased to introduce the 2.0T FSI Stage III GTX Turbocharger System. Producing over 405 horsepower on 93 (R+M)/2 octane and 449 HP in racing configurations, Stage III GTX places the 2.0T FSI's accelerative performance in the same league as that of large V8 supercharged muscle cars and sub $400,000 exotic sports cars.

Important note* While the hardware in this listing is compatible with your vehicle it is possible that the required tuning is not. To confirm ECU tuning is available for your car, your vehicle's ECU box code must be identified. If you own VAG COM, OBDeleven, Carista, or have access to factory VW/Audi diagnostic tooling, you can follow this guide to identify your ECU box code. You can also visit either New German Performance shop location and our staff will be happy to assist. The customer assumes all risk if this turbocharger purchased and installed without first confirming the required software is available. No returns are accepted for installed turbocharger kits.

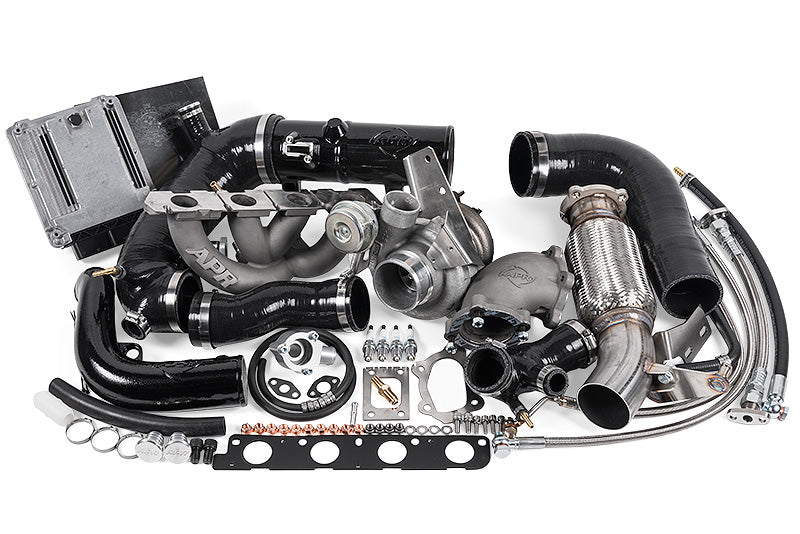

Components

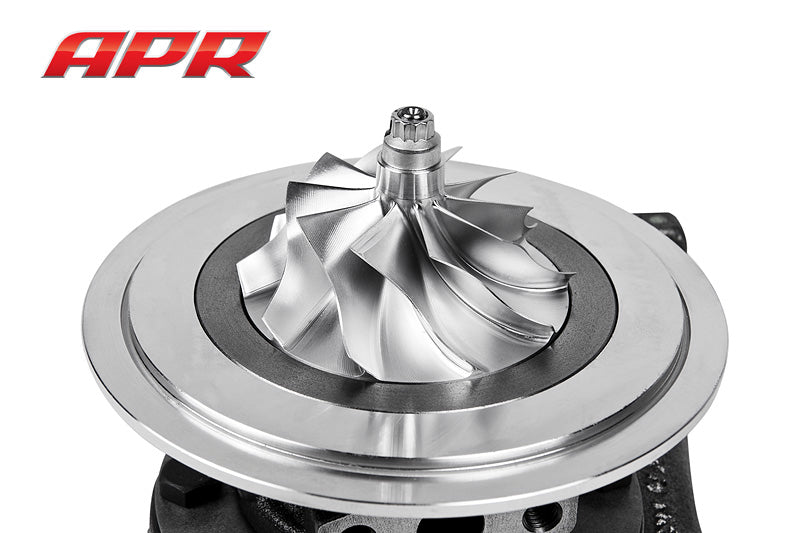

Turbocharger

At the heart of Stage III GTX is a GTX2867R turbocharger, consisting of the latest technologies from Le Mans’ winning turbo manufacturer, Garrett Honeywell. The internally gated unit features a fully-machined, ten-blade billet compressor wheel and a dual ball bearing oil and water-cooled CHRA. APR’s Engineers spent countless hours testing turbine inlet and A/R sizes in order to decrease turbocharger lag without negatively impacting peak power. The newly developed compressor housing utilizes anti-surge porting, which greatly complements the lightning fast spool characteristics of this unit and grants APR’s Engineers the ability to deliver massive levels of torque inducing boost pressure, even in the lower RPM range.

APR Stage III GTX Software

With the significant amount of changes included in the APR Stage III GTX Turbocharger System, APR’s Engineers spent months recalibrating the engine management system to operate smoothly as if intended by the OEM. Thanks to APR’s incredible proprietary calibration suite, data logging software and full access to the coding structure of the ECU, appropriate and intelligent changes are made to ensure flawless drivability and excellent performance without compromise.

Exhaust Manifold

Attached to the turbocharger is APR’s investment-cast, super alloy, nickel-chromium-based Inconel 625 Manifold featuring APR’s Sequential Exhaust Pulse runner lengths. Unlike hand welded tubular manifolds, Inconel is a very high temperature resistant material designed to withstand extreme exhaust gas temperature changes without expanding, contracting, melting or cracking under stress. This material is typically found only at the highest levels of professional motorsport racing where reliability is essential to success.

Turbo Outlet Pipe

To provide unrestricted and smooth airflow from the turbocharger to the intercooler, the APR Stage III GTX Turbocharger System includes a cast enlarged turbo outlet pipe to properly deliver the additional airflow from the larger turbocharger.

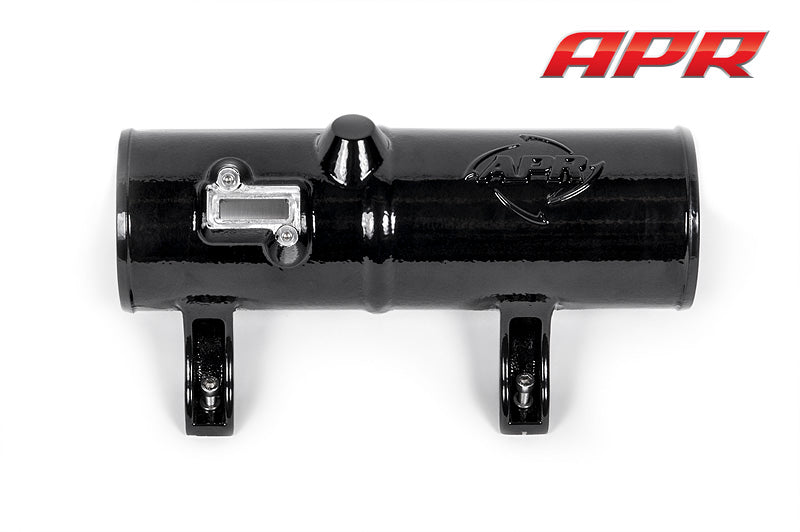

Mass Airflow Housing

The 2.0T FSI's engine management relies on load calculations to accurately control the engine. Calculations are made by measuring airflow across the Mass Airflow Sensor and this is a critical component of the APR Stage III GTX Turbocharger System.

The small and restrictive factory unit is removed and replaced with the much larger housing. To ensure accuracy, APR’s MAF housing is cast in the United States of America and CNC machined in house at APR to ensure repeatable results. The long, precision-machined housing features a honeycomb airflow straightener to further aid in accurately reading airflow levels. Simply enlarging the MAF housing is not permissible without accurate adjustments to the factory engine management system, which is included with APR Stage III GTX Turbocharger System.

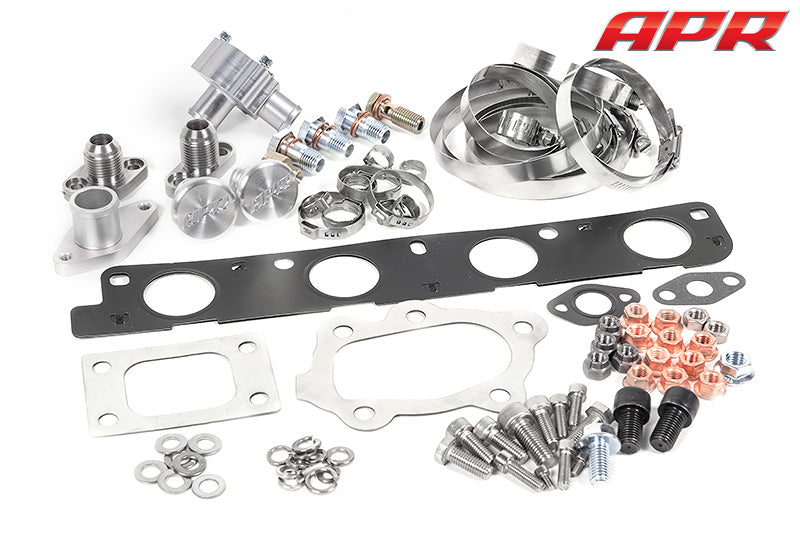

High Pressure Fuel Rail Valve

The factory 2.0T gasoline direct injection injectors require higher than factory fuel rail pressure to achieve targeted air fuel ratios under high load, wide open throttle operation. APR’s Low Pressure Fuel Pump delivers the desired volume of fuel to the APR High Pressure Fuel Pump, which provides increased fueling headroom over the factory unit. However, the factory High Pressure Fuel Rail Valve limits maximum rail pressure below the desired level. The included APR High Pressure Fuel Rail Valve is calibrated to increase the maximum rail pressure to levels necessary for proper operation.

Cast Downpipe

The APR Stage 3 downpipe features an investment cast, T304 inlet and outlet that perfectly match the 5-bolt flange’s awkward shape. By casting this piece, APR’s engineers were able to make an extremely smooth and organic shape, otherwise not achievable with fabrication alone. The system smoothly necks down to the 76mm design over a long distance, making an ideal flow path for exhaust gasses and power. The flex section is a low-profile design that will not internally fray, billow and fail like others on the market and is TIG welded with argon back purging to the casting. The o2 sensor bung, turbo flange, and mounting bracket flange are all cast into the design, and the mounting bracket itself is made from a thick, high-quality piece of billet stainless.

For customers with an APR Downpipe Exhaust System, the included portion replaces the upper section and mates directly to the APR Catalyst Midpipe. For customers without an APR Cast Downpipe Exhaust System, the APR Catalyst Midpipe is available separately. The midpipe is fully compatible with the factory catback exhaust system.

APR Stage III GTX ECU Upgrade Calibration Report

| Specs: | Stock | 91 Octane | 93 Octane | 100 Octane |

|---|---|---|---|---|

| Rev Limit | 6,800 RPM | 7100 RPM | 7100 RPM | 7100 RPM |

| Speed Limit | 155 MPH | Unlimited | Unlimited | Unlimited |

| Power (HP) | 200 HP | 386 HP | 405 HP | 449 HP |

| Torque (LB-FT) | 207 TQ | 346 TQ | 363 TQ | 376 TQ |

Requirements and Recommendations

Fueling

The APR HPFP is required. OEM Bosch HDEV1 High Flow Injectors (06F 906 036 F) are required. A 200 Bar Bosch High Pressure Rail Sensor (06J 906 051 D) is required for Pre model year 2007 vehicles.

Exhaust System

The APR FWD Midpipe or APR AWD Midpipe is required if the vehicle is not already equipped with an APR downpipe.

Intake System

The APR Carbon Fiber Intake System is recommended and required to meet the advertised power levels (R/S3 platform).

Intercooler

The APR Intercooler System is recommended and required to meet the advertised power levels.

Transmission

APR cannot make any guarantees as to the longevity of the OEM manual transmission clutch or DSG/S Tronic clutches in every transmission and therefore an upgraded clutch is recommended and may be required depending on the stage, octane, driving style and clutch health.

Engine Internals

Stage III power, torque, boost, cylinder pressure and temperature levels and more are substantially higher than stock. APR cannot make any guarantees as to the longevity of the factory engine internals or all factory components on every engine. As such, APR recommends upgrading rods/bearings and pistons/rings for increased engine reliability and longevity, especially when using race fuel.

Spark Plugs

NGK BKR8EIX, gapped to 0.022" ±0.002" or 0.55mm ±0.05mm with a change interval of 10-15,000 mi or 16-24,000 km spark plugs are included and required.

Oil, Coolant and Lubrication

An oil change is required when this turbocharger kit is installed. This allows for proper break in of the new turbocharger. Liqui Moly oil change kits are available for purchase with this kit as an option above